Visual Positioning and Automation: A Perfect Match for Smart Factories

Introduction

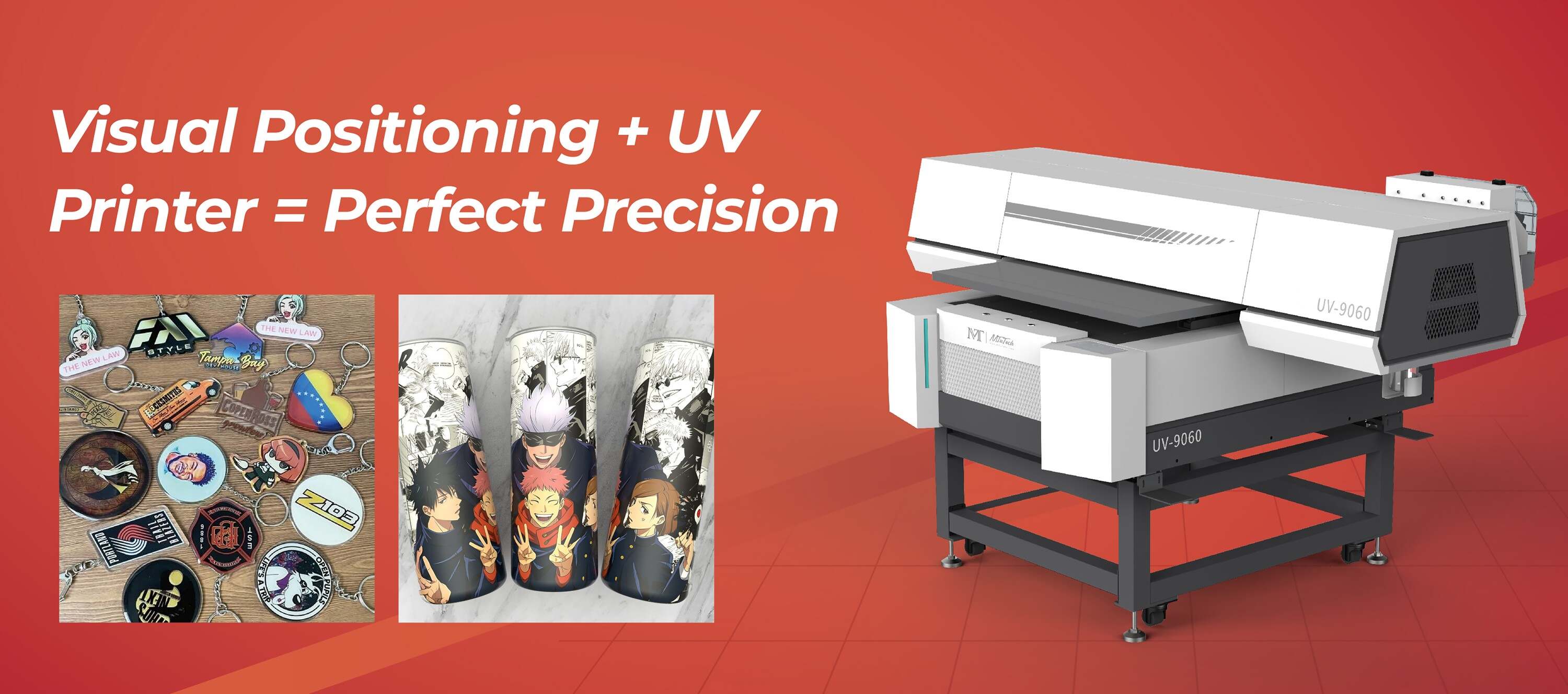

In the era of Industry 4.0, the synergy between visual positioning and automation is revolutionizing how smart factories operate. Visual positioning UV printers are no longer just about high-quality output—they’re about seamless integration into automated production lines that demand speed, accuracy, and minimal human intervention. This blog explores how visual positioning technology enhances automation and why it's the cornerstone of the future in industrial UV printing.

The Role of Visual Positioning in Automation

Visual positioning systems use high-resolution cameras and intelligent software to detect object placement, shape, orientation, and registration marks. In automated environments, this data enables UV printers to auto-align prints with extreme precision, eliminating the need for manual calibration or setup. The result? Faster workflows, fewer errors, and greater consistency across production batches.

Benefits of Visual Positioning in Smart Factories

- **Improved Production Speed**: Visual positioning significantly reduces idle time by automating alignment and print head adjustments.

- **Real-Time Adaptation**: As objects move along conveyor belts, printers can adjust on-the-fly using live image feeds.

- **Reduced Human Intervention**: Operators can oversee more machines at once, lowering labor costs and increasing throughput.

- **Enhanced Repeatability**: Achieve the same quality print on thousands of units without recalibration.

Key Applications in Smart Manufacturing

- **Electronics**: Visual positioning helps precisely print on irregular PCBs and casings.

- **Packaging**: Ensures graphics are centered on flexible or variably shaped packaging materials.

- **Textiles**: Allows for accurate layering on pre-cut fabric or curved surfaces.

- **Automotive Components**: Perfect for marking, branding, or adding safety instructions to parts.

How Visual Positioning UV Printers Integrate with Robotics

Smart factories often pair UV printers with robotic arms, conveyors, and pick-and-place systems. Visual positioning bridges the communication gap between hardware by supplying exact coordinates and timing cues. This means your printer doesn’t just print—it becomes an intelligent node in a larger, orchestrated automation system.

Data Collection and Quality Assurance

Advanced visual positioning systems can also log inspection data. For every printed item, the system captures alignment accuracy, print quality, and pass/fail status. This data can feed into ERP systems, allowing for traceability, predictive maintenance, and improved decision-making in real-time.

Cost and ROI Considerations

Although visual positioning UV printers carry a higher upfront cost, the long-term savings are massive. Reduced waste, faster turnaround, and minimized error rates result in quicker ROI. For factories running high-volume or complex orders, the payback period is dramatically shortened thanks to efficiency and automation gains.

Future Outlook

As AI and machine learning become more embedded in factory tech stacks, visual positioning systems will become even smarter. Expect adaptive alignment, defect prediction, and self-calibration features that make these printers almost entirely autonomous. Smart factories of the future will rely heavily on this technology to maintain competitiveness and product consistency at scale.

Conclusion

Visual positioning and automation are a match made in Industry 4.0 heaven. By combining these technologies, smart factories can dramatically increase efficiency, reduce waste, and ensure flawless results at scale. Investing in visual positioning UV printers is not just about better prints—it’s about building the intelligent, automated workflows of the future.

Upgrade your factory floor with our smart-ready visual positioning UV printer — engineered for flawless automation, accuracy, and efficiency.