-

Company Advantage

We promoted the technical innovation in the digital inkjet printing facilities production.

The MT Industry has been keeping developing! -

Customer Service

Please contact us if you have any doubt, problem or trouble regarding to our products. Just click “LIVE CHAT”!

-

Guarantee Policy

We provide with 1 year warranty, but gain PERMANENT GUARANTEE with continuous ink order!

-

Payment Terms

We are committed to providing the most convenience payment term; the Client can choose T/T, L/C, PayPal and West union!

-

Packing Standard

The most environmentally friendly and strong packaging, the clients no need worry in the delivery process!

-

Transportation & Delivery

We provide the most convenient, safe, fast Transport after we get the purchase order, even provide home delivery!

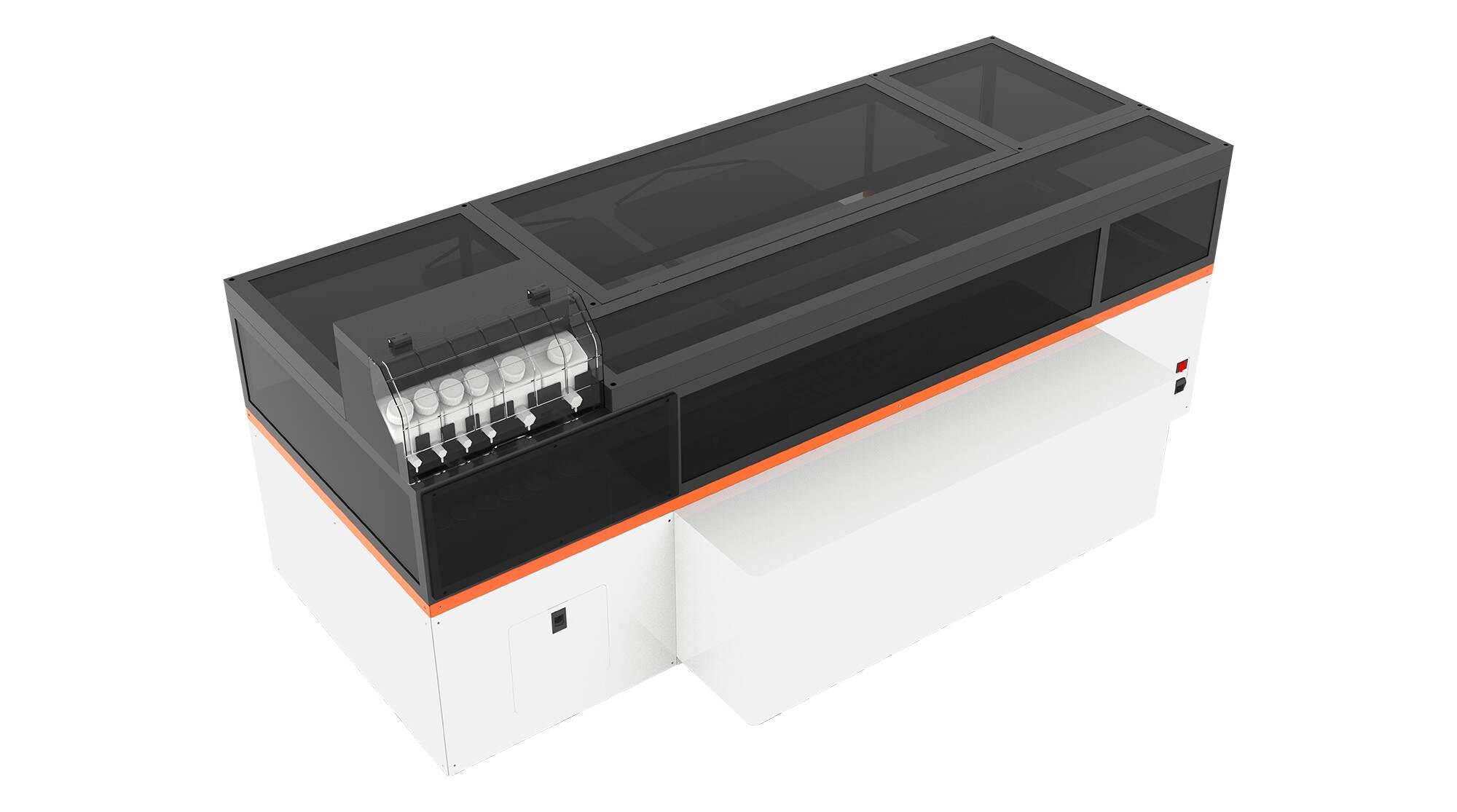

We're gonna to discover the World of MTuTech DTG Printing today ! Our double station DTG printer allows for high-quality, full-color, and detailed prints on a variety of fabrics, making it printing ideal for custom apparel production. It's very easy to get bright prints & amazing print speed & reliable and easy to use equipment. DTG is especially favored by businesses that focus on on-demand printing or short-run production, perfect for start-ups, medium-sized and large-volume print shops.

We're gonna to discover the World of MTuTech DTG Printing today ! Our double station DTG printer allows for high-quality, full-color, and detailed prints on a variety of fabrics, making it printing ideal for custom apparel production. It's very easy to get bright prints & amazing print speed & reliable and easy to use equipment. DTG is especially favored by businesses that focus on on-demand printing or short-run production, perfect for start-ups, medium-sized and large-volume print shops.

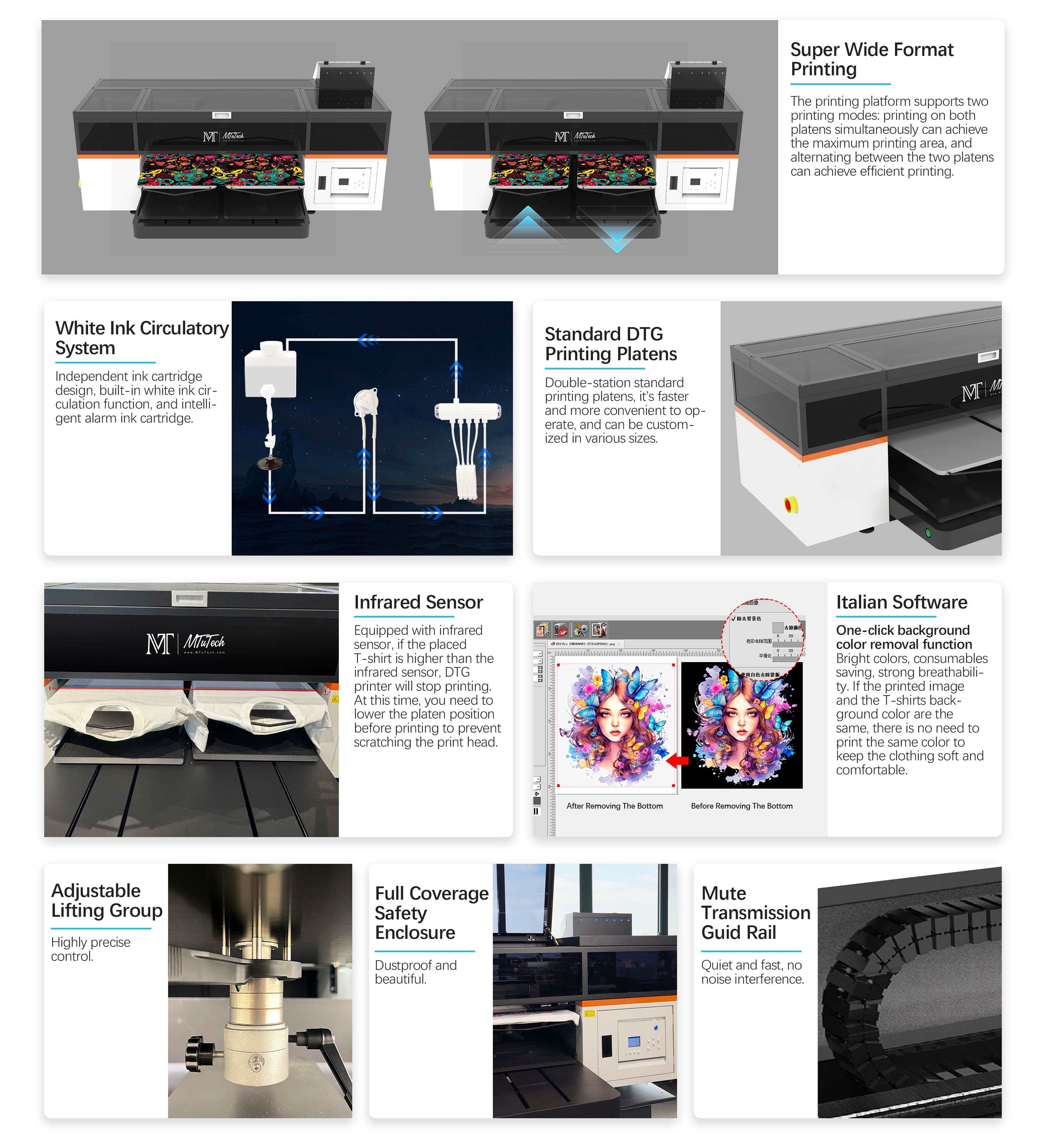

MT- DTG Pro DTG T-shirt printer, with double-stations that allows you to print T-shirts one after one continuously, when it is printing shirts on one station, you can replace with a new shirt on another station, so it is very fast and high-efficient.

What's DTG Printer?

A Direct-to-Garment (DTG) printer is a type of digital printer specifically designed for printing designs directly onto textiles, such as t-shirts, hoodies, and other clothing items.

Versatile DTG Applications

If you want your cotton fabric to have a perfect printing effect, the DTG printer can well meet your direct printing needs and can print cotton, cotton/polyester blends, polyester and other material products. Our DTG printer is more than a t-shirt printer. Whether for t-shirts, polo shirts, hoodies, sweatshirts, overalls, jean jackets, jeans, sweatpants, shorts, shoes, towels, cushion covers, pillowcases, tote bags, scarves, can coolers, hats, dishcloths and so much more, DTG printer can handle all of them.

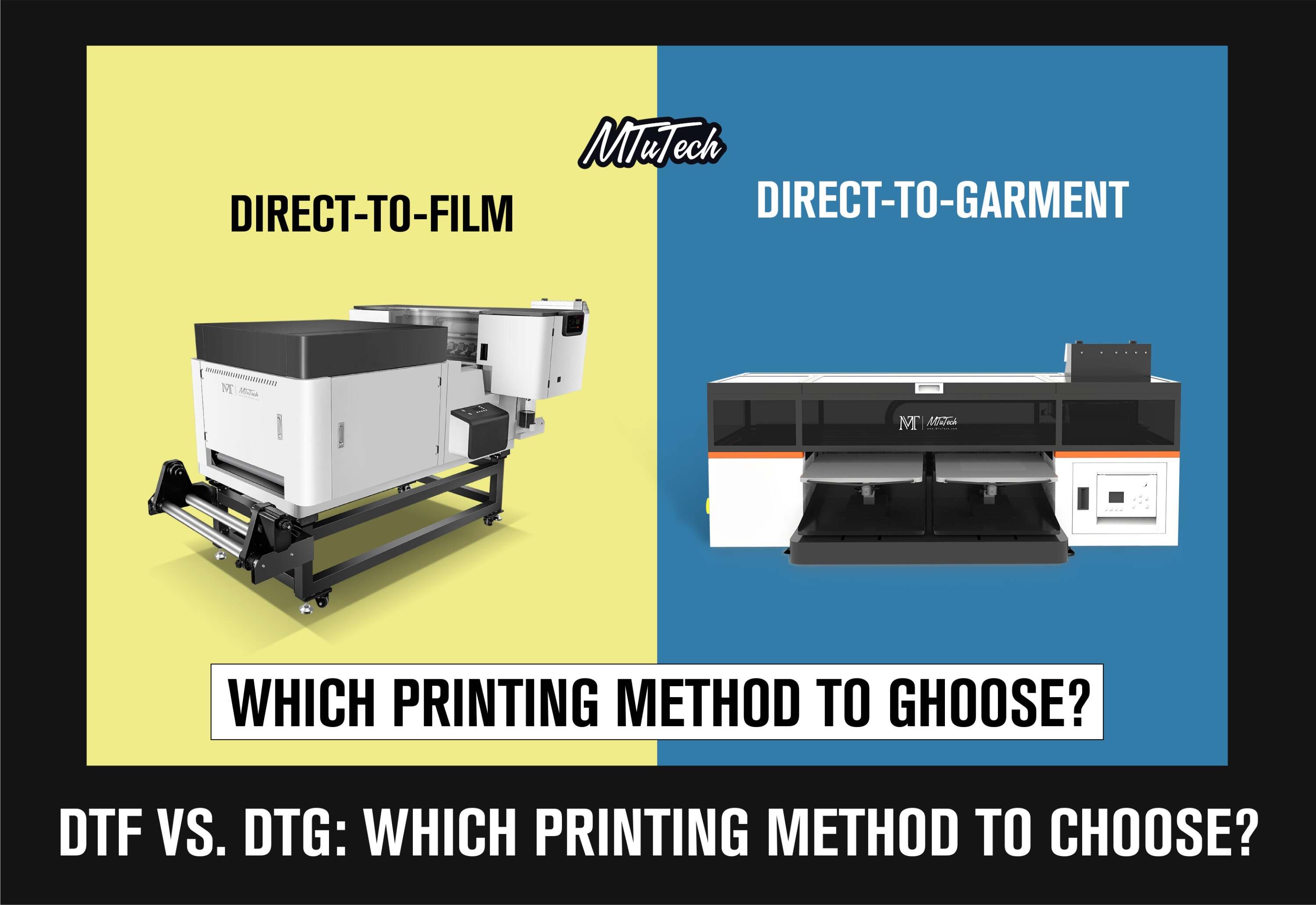

DTG VS DTF

| Pros and Cons | DTG | DTF |

Transfer films | Does not need transfer films | Need transfer films |

Pre-treatment | Requires pre-treatment process, which means you will need an extra step before printing. | Require no pre-treatment |

Applications | Work well on flat surface printing and as the name suggests: only garments. | Can print on different types of surfaces, and more than just garments such as t-shirts, hoodies, hats, tote bags etc. |

| Consumables | Uses more white ink for darker garments | Requires adhesive powder and special film |

Advantages of DTG Printer

Product Details of DTG Printer

How Does DTG Printer Work?

Here's a step-by-step breakdown of the entire DTG printing process:

1)Design Creation

Create and prepare the design on a computer. The design is adjusted for size, resolution, and color profiles to ensure it prints correctly on the chosen garment.

2)Pre-Treatment

Pre-treatment is essential when printing on dark or colored garments, as it helps the white ink to adhere properly and increase color vibrancy. The application of a pretreatment liquid is always required when printing white ink on a garment.

How to pre-treatment ?

The pre-treatment liquid is applied to the area of the garment where the design will be printed. This can be done using a pre-treatment machine, spray gun, or roller.

The amount and evenness of application are crucial; too much or too little can affect the print quality.

3)Drying:

Once the pre-treatment is applied, the garment is placed under a heat press at around 330°F (165°C) for 10-15 seconds. This step dries the solution and flattens the fibers of the fabric, creating a smooth surface for printing.

4)Printing

The pre-treated garment is placed onto the DTG printer's platen (the flat surface that holds the garment in place). Care is taken to ensure the garment is properly aligned to avoid misprints.

The printer head moves back and forth over the garment, spraying tiny droplets of ink onto the fabric in the exact pattern of the digital design.For dark garments, the printer typically first lays down a white ink base layer, followed by the colored inks on top. On light garments, color inks are usually applied directly. The ink is absorbed by the fabric, creating a soft, detailed, and vibrant print.

5) Curing

When printing is finished, you'll need to cure the garment using a heat press or a forced air conveyor dryer. This allows the ink to set.

Curing equipment required in DTG: Heat press vs Oven Dryer

6) Quality Check

Inspection: The printed garment is inspected for any issues such as misalignment, color inconsistencies, or incomplete curing.

Touch-Up: If necessary, minor touch-ups can be made, or the garment can be re-pressed to improve the quality.

7) Finishing and Packaging

Final Inspection: A final check ensures that the print is of high quality and meets customer specifications. The garment is folded, packaged, and prepared for shipping or sale.

In Conclusion

Our aim is provide great printers for those who seek it and provide one-stop printing solution. Our printing solution portfolio includes a wide range of textile printers for entry-level, mid-market segment, and high-volume production. Whether you're looking to grow your direct to garment business, direct to film printing capability or direct to fabric printing, you can get the complete printing solution from MTuTech. We’re always ready to help you every step of the way.

Specifications

| Model Type | DTG Priner MT-DTG Pro | ||

|---|---|---|---|

| Printhead | 4pcs Printheads | ||

| Ink Type | Eco-friendly Pigment Ink | ||

| Color | CMYK + White | ||

| Applications | Suits for custom apparel printing, such as t-shirts, hoodies, tote bags etc. | ||

| Printing Speed | Print a T-shirt in 40 seconds. | ||

| Printing Height | 0-3mm | ||

| Printing Resolution | 720*1200dpi (4pass) | ||

| Printer Size | 1900mm * 1350mm * 870mm | ||

| Weight | 252kg | ||

| RIP Software | DeVstudio | ||

| Printing Environment | Temperature 18-30°C, Humidity 35%-65% |