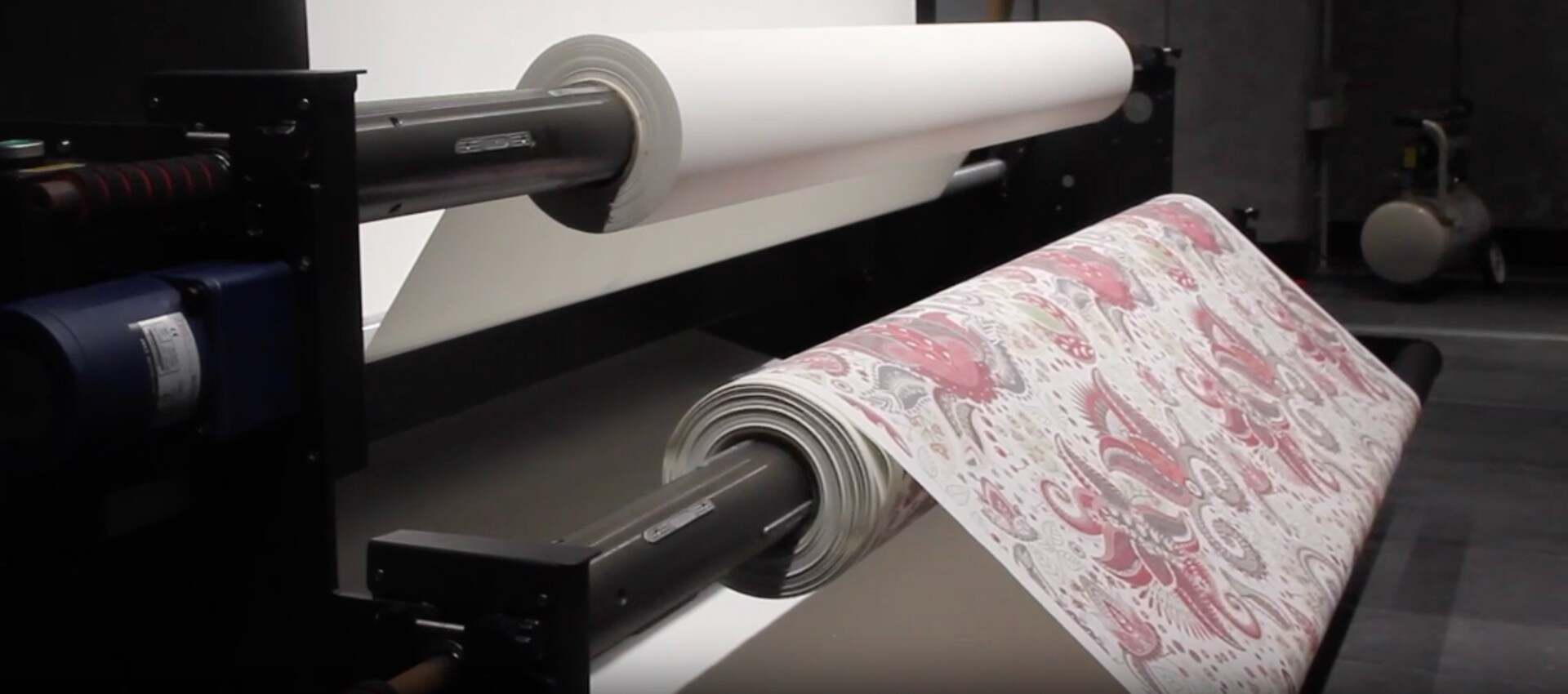

Dye Sublimation Printer

Dye Sublimation Printer Options

Industrial 1.9m 8Pcs Epson S3200 | 10,000 Meters Rewinding

Dye Sublimation Printer MT-P1908Pro Max

New generation industrial dye sublimation printer designed to increase your productivity and competitiveness!

| Model | MT-P1908Pro Max |

|---|---|

| Printhead | 8pcs Epson S3200 Printheads |

| Print Width | 1900mm (74.80‘’) |

| Max Print Speed | 662m²/h |

| Print Resolution | 1200dpi |

| Colors | CMYK + Fluorescent color |

| Ink | Sublimation Ink |

| Print Head Height | 2mm-5mm |

| Ink Droplet Size | 3.8PL-12PL |

Commercial 1.9m 8Pcs Epson i3200 | 5,000 Meters Rewinding

Dye Sublimation Printer MT-P1908A1

High Productivity 8pcs Epson i3200 Printheads Dye Sublimation Printer .

| Model | MT-P1908A1 |

|---|---|

| Printhead | 8pcs Epson i3200 Heads |

| Print Width | 1900mm(74.80‘’) |

| Max Print Speed | 370m²/h |

| Print Resolution | 1200dpi |

| Colors | CMYK+Fluorescent color |

| Ink | Dye Sublimation Ink |

| Print Head Height | 2mm-5mm |

| Ink Droplet Size | 3.8PL-12PL |

|

MT-P1908Pro Max

|

MT-P1908A1

|

|

8pcs Epson S3200 Printheads

|

8pcs Epson i3200 Heads

|

|

1900mm (74.80‘’)

|

1900mm(74.80‘’)

|

|

662m²/h

|

370m²/h

|

|

1200dpi

|

1200dpi

|

|

CMYK + Fluorescent color

|

CMYK+Fluorescent color

|

|

Sublimation Ink

|

Dye Sublimation Ink

|

|

2mm-5mm

|

2mm-5mm

|

|

3.8PL-12PL

|

3.8PL-12PL

|

Model |

|---|

Printhead |

Print Width |

Max Print Speed |

Print Resolution |

Colors |

Ink |

Print Head Height |

Ink Droplet Size |

Dye Sublimation Printers – Precision Printing for Growing Businesses

Unlock vivid, high-speed textile printing for apparel, signage, home décor, and more. MTuTech dye sublimation printers are built to deliver vibrant output, industrial productivity, and cost-efficiency at scale.

Why Choose MTuTech Dye Sublimation Printers?

Brilliant, long-lasting colors using advanced sublimation ink technology that bonds permanently with fabric fibers

High-speed, high-volume performance for demanding production schedules

Versatile media compatibility including polyester fabrics, coated ceramics, aluminum sheets, and more

Cost-efficient workflow with minimal waste, low maintenance, and optimized ink usage

Scalable models to suit startups, mid-sized producers, and industrial manufacturers.

Performance Highlights of MTuTech Dye Sublimation Printers

Available in print widths up to 1.8 meters, supporting bulk fabric rolls

Powered by industrial-grade printheads (compatible with Kyocera or Epson i3200) for long life and precision

Print resolutions up to 2400 DPI with multiple pass modes for different fabric needs

Supports daily production up to 3500–4000 square meters, depending on the model

Integrated infrared drying system and vacuum bed for smooth feeding and fast drying

Advanced ink degassing system prevents bubbles and ensures consistent ink flow

Compatible with major RIP software with fabric-specific ICC profiles for color fidelity

Supports refillable dye-sublimation aqueous inks for low-cost operation

Find the Right Dye Sublimation Printer for Your Needs

Entry-Level Printers (Up to 24” Width)

Ideal for:

Startups and small custom businesses

Personalized gifts such as mugs, bottles, and phone cases

Apparel prototypes and short-run production

These compact models are easy to use and budget-friendly.

Mid-Range Production (44” – 64” Width)

Ideal for:

Apparel and soft signage production

Custom home textiles such as pillowcases and tapestries

Promotional merchandise in volume

These printers balance speed, flexibility, and consistent output.

Industrial High-Volume Printers (64”+ Width)

Ideal for:

Large-scale factories operating 24/7

Sportswear, curtains, upholstery, and large format signage

Exporters and manufacturers with bulk orders

Built for continuous operation and large-volume output.

Mtutech Dye Sublimation Printer Technical Specifications Overview

Printing technology: Drop-on-demand Piezo inkjet

Ink type: Dye sublimation aqueous inks

Color configuration: 4-color CMYK

Max media thickness: Up to 20mm

Print resolution: Up to 2400 dpi

Interface: USB 3.1 high-speed

Supported formats: JPEG, TIFF, PDF, BMP (RGB & CMYK)

Drying system: Infrared heaters with blower

Power: 220V, 50/60Hz, low energy usage

Print speed: Ranges from 68 to 210 sq.m/hour depending on mode

Industries That Trust Dye Sublimation Printing

Fashion and Sportswear

Custom printing for jerseys, leggings, activewear, and fashion items with lasting durability and vibrant design.

Home Furnishing and Décor

Create custom curtains, bedsheets, cushions, and wall tapestries with sharp, vivid prints on fabric.

Advertising and Signage

Produce flags, banners, and retail graphics with color-rich, fade-resistant prints for indoor and outdoor use.

Corporate Gifting and Merchandise

Print on mugs, keychains, photo panels, and other promotional items with personalized branding.

How Dye Sublimation Printing Works

Print your design on sublimation transfer paper using specialized sublimation inks

Use a heat press to transfer the image onto the substrate at temperatures around 400°F

The ink turns into gas and fuses with the substrate at a molecular level

The result is a permanent, high-definition print that does not peel or fade

Dye Sublimation vs. Other Printing Technologies

Color Vibrancy

Dye sublimation delivers excellent color vibrancy with bright, vivid results. DTG printing provides good color on cotton fabrics, while screen printing offers moderate color vibrancy, especially for detailed designs.

Durability

Dye sublimation prints are highly durable as the ink becomes part of the material. DTG prints are moderately durable and may fade over time. Screen printing is also highly durable, especially for bold designs.

Fabric Compatibility

Dye sublimation works best on polyester and polymer-coated surfaces. DTG printing is primarily suitable for 100% cotton fabrics. Screen printing supports a wide range of fabrics but may require different setups.

Setup Time

Dye sublimation has a fast and simple setup process. DTG requires moderate preparation. Screen printing involves a long setup, especially when preparing screens for multi-color designs.

Ideal Use Cases

Dye sublimation is ideal for apparel, promotional gifts, home décor, and signage on polyester materials. DTG is best for small runs of cotton t-shirts with detailed artwork. Screen printing is ideal for bulk production, especially when printing large quantities of the same design.

Why MTuTech Dye Sublimation Printer Stands Out

Over a decade of experience in digital printing technology

Dedicated customer support and training services

Trusted by over 1,000 businesses worldwide

Competitive pricing and international shipping

Local service availability and reliable spare parts supply

Book a Live Demo or Request a Quote

Looking for a high-speed dye sublimation printer tailored to your business?

Schedule a live demo or get a personalized quote from our technical team.

Contact us now to explore models and pricing.

Want to dive deeper into sublimation printing trends and tips? Learn more in our blogs and explore expert insights.

FAQs About Dye Sublimation Printers

What materials can I print on with a dye sublimation printer?

Polyester fabrics and polymer-coated materials such as mugs, plates, phone cases, and aluminum panels.

Are the prints washable and durable?

Yes, the ink becomes part of the material, ensuring the print will not crack, fade, or peel, even with regular use.

Is dye sublimation eco-friendly?

Yes, it uses water-based inks and does not require harmful chemicals, making it a sustainable printing solution.

Can I use this for mass production?

Yes, MTuTech offers industrial models built for high-volume production and continuous operation.

What print sizes are available?

Our printer models range from 24-inch to 74-inch width options, suitable for businesses of all sizes.