The world of Cylinder UV Printing Technology is evolving rapidly, offering businesses new possibilities to customize cylindrical surfaces such as bottles, cans, tumblers, and industrial components with vibrant, high-quality prints. As the demand for personalized products and sustainable printing practices grows, emerging trends in Cylinder UV Printing are driving innovation and reshaping the industry.

The world of Cylinder UV Printing Technology is evolving rapidly, offering businesses new possibilities to customize cylindrical surfaces such as bottles, cans, tumblers, and industrial components with vibrant, high-quality prints. As the demand for personalized products and sustainable printing practices grows, emerging trends in Cylinder UV Printing are driving innovation and reshaping the industry.

In this article, we’ll explore the top emerging trends in Cylinder UV Printing Technology and how these advancements can benefit businesses looking to stay ahead of the curve.

✅ Why Staying Up-to-Date with Cylinder UV Printing Trends is Essential

Keeping up with the latest trends in Cylinder UV Printing Technology offers several advantages:

● Enhanced Print Quality: Access to cutting-edge technology that delivers sharper, more vibrant prints.

● Increased Production Efficiency: Faster printing speeds and reduced setup times.

● New Revenue Opportunities: Ability to offer innovative and personalized products to customers.

● Sustainable Practices: Adoption of eco-friendly printing solutions to meet environmental standards.

Top 10 Emerging Trends in Cylinder UV Printing Technology

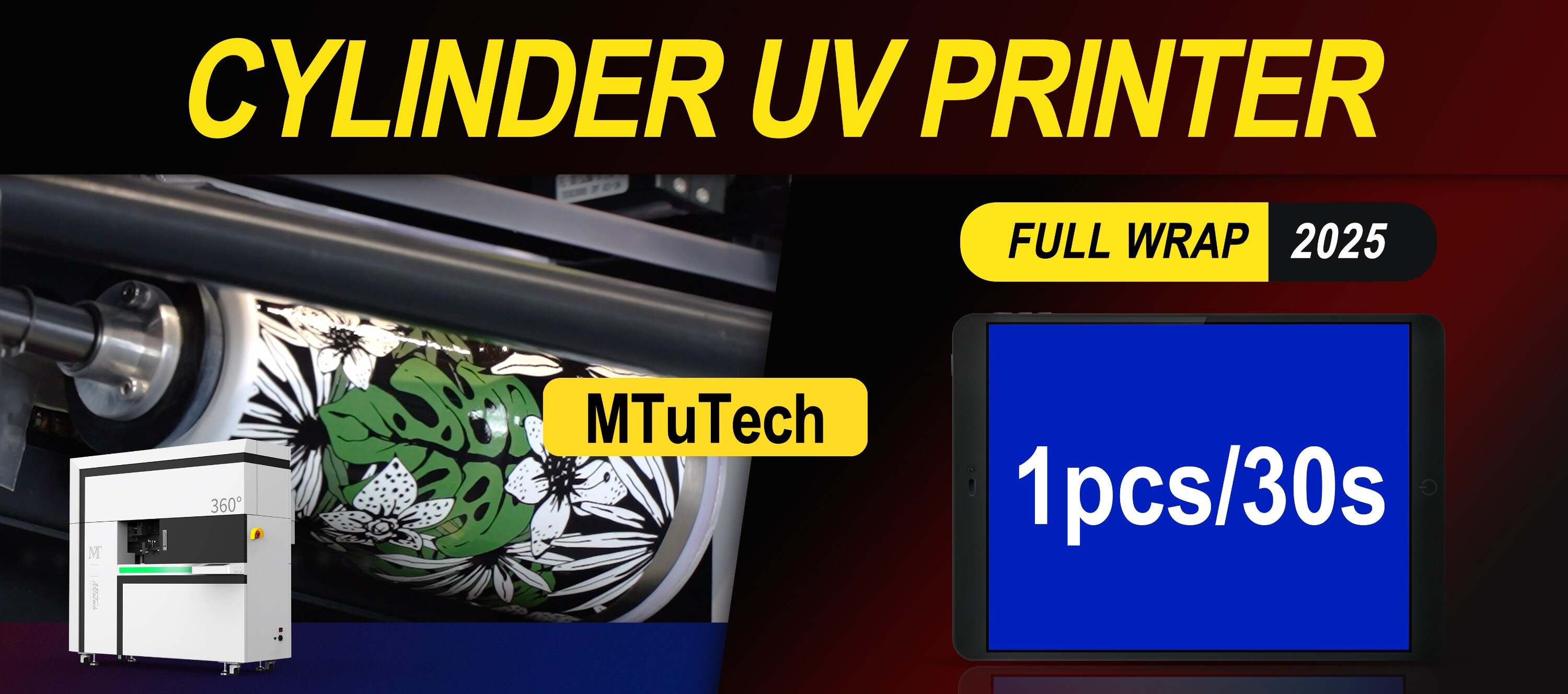

️ 1. High-Speed Cylinder UV Printing for Mass Production

As consumer demand for personalized products grows, high-speed Cylinder UV Printers are becoming a game-changer for businesses looking to scale their production. New models offer faster curing times, improved print speeds, and enhanced rotary fixtures that enable high-volume printing without compromising quality.

● ✅ Benefit: Increased output capacity with reduced turnaround times.

● ✅ Industries Impacted: Beverage, cosmetics, and promotional product sectors.

Pro Tip: Invest in high-speed UV printers with automated loading and unloading systems for seamless production.

2. Advanced 3D Printing Effects with UV Texturing

A major trend in Cylinder UV Printing is the ability to create 3D texturing and embossing effects directly onto cylindrical objects. UV layering technology adds tactile finishes to products, enhancing the look and feel of the final print.

● ✅ Benefit: Adds a premium, high-end feel to packaging and promotional items.

● ✅ Industries Impacted: Luxury packaging, perfume bottles, and beverage cans.

Pro Tip: Experiment with different UV layering techniques to create unique textures and standout designs.

3. Integration of IoT and Smart Printing Technology

The Internet of Things (IoT) is making its way into Cylinder UV Printing, enabling real-time monitoring, remote diagnostics, and predictive maintenance. IoT-enabled printers can automatically adjust settings based on object size, material, and ink requirements.

● ✅ Benefit: Reduced downtime and increased operational efficiency.

● ✅ Industries Impacted: Manufacturing, industrial labeling, and large-scale production facilities.

Pro Tip: Opt for IoT-integrated UV printers to monitor performance and optimize workflows remotely.

4. Expanded Color Gamut and Metallic Finishes

To meet the growing demand for vibrant and dynamic prints, expanded color gamuts and metallic UV inks are becoming popular in Cylinder UV Printing. These advanced inks allow for more accurate color reproduction and add a luxurious, eye-catching finish.

● ✅ Benefit: Greater flexibility in achieving complex color combinations and unique designs.

● ✅ Industries Impacted: Cosmetics, craft beverages, and premium promotional items.

Pro Tip: Use metallic UV inks to create attention-grabbing packaging designs for high-end products.

⚡ 5. Variable Data Printing (VDP) for Mass Customization

Variable Data Printing (VDP) is gaining traction in the Cylinder UV Printing space, enabling businesses to personalize individual products with unique text, QR codes, and graphics. This technology is perfect for producing limited-edition items and targeted promotional campaigns.

● ✅ Benefit: Personalization at scale without additional setup time.

● ✅ Industries Impacted: Event promotions, beverage branding, and product packaging.

Pro Tip: Leverage VDP to create unique customer experiences with personalized designs and serialized packaging.

6. Eco-Friendly and Sustainable Printing Solutions

With increasing emphasis on sustainability and eco-friendly practices, businesses are adopting LED UV lamps and water-based UV inks that reduce energy consumption and environmental impact.

● ✅ Benefit: Compliance with environmental regulations and improved brand reputation.

● ✅ Industries Impacted: Food and beverage, cosmetics, and healthcare sectors.

Pro Tip: Switch to LED UV curing systems to reduce power consumption and extend equipment lifespan.

7. Artificial Intelligence (AI) for Print Optimization

Artificial Intelligence (AI) is transforming Cylinder UV Printing by automating print optimization processes. AI-powered software analyzes real-time data to fine-tune ink application, curing time, and print resolution for optimal results.

● ✅ Benefit: Reduced errors, increased consistency, and higher overall efficiency.

● ✅ Industries Impacted: Large-scale manufacturers and high-volume printers.

Pro Tip: Use AI-driven workflow optimization to minimize waste and improve print quality.

8. Hybrid UV Printing for Enhanced Material Compatibility

Hybrid UV Printing combines the best of UV and solvent-based printing, allowing printers to work with a broader range of materials. This trend expands the range of applications and opens up new possibilities for custom product decoration.

● ✅ Benefit: Increased flexibility in printing on challenging surfaces.

● ✅ Industries Impacted: Automotive parts, promotional products, and industrial labeling.

Pro Tip: Invest in hybrid UV printers to offer more versatile and diverse product options.

9. Augmented Reality (AR) Integration for Interactive Packaging

Augmented Reality (AR) is revolutionizing product packaging by adding interactive elements to printed designs. QR codes and AR markers allow consumers to engage with brands through immersive digital experiences.

● ✅ Benefit: Enhanced customer engagement and brand loyalty.

● ✅ Industries Impacted: Beverage, cosmetics, and consumer electronics.

Pro Tip: Incorporate AR elements into packaging designs to create interactive experiences for consumers.

10. Fully Automated Cylinder UV Printing Systems

Automation is taking Cylinder UV Printing Technology to new heights, with fully automated systems that handle everything from object loading to final curing. These systems streamline the production process and minimize human intervention.

● ✅ Benefit: Improved efficiency, reduced labor costs, and higher production capacity.

● ✅ Industries Impacted: High-volume manufacturing and commercial printing facilities.

Pro Tip: Integrate fully automated systems with ERP/CRM platforms for seamless order management.

How These Trends Impact Key Industries

1. Beverage Industry

● High-speed UV printing enables mass production of custom-printed bottles and cans.

● Metallic finishes and AR integration create premium packaging for craft beverages.

2. Cosmetics and Personal Care Industry

● 3D texture effects and expanded color gamuts enhance the visual appeal of perfume bottles and cosmetic containers.

● IoT-enabled printers ensure quality control and consistency in mass production.

3. Packaging and Promotional Products

● Variable Data Printing (VDP) allows for personalized promotional items and event giveaways.

● Hybrid UV Printing increases the range of compatible materials for product decoration.

4. Industrial Applications

● AI-powered print optimization reduces errors and improves print consistency on industrial parts.

● Fully automated systems enhance efficiency in high-volume manufacturing environments.

Case Study: Beverage Brand Increases Sales by 40% with AR-Enabled Packaging

The Challenge:

A craft beverage company wanted to enhance customer engagement and differentiate its product packaging from competitors.

The Solution:

The company adopted Cylinder UV Printing Technology with Augmented Reality (AR) integration, allowing consumers to scan QR codes on bottles and access interactive content.

Results:

● ✅ 40% increase in customer engagement.

● ✅ 25% boost in repeat purchases.

● ✅ Enhanced brand loyalty and social media sharing.

Comparison of Traditional vs. Emerging Cylinder UV Printing Trends

Feature | Traditional UV Printing | Emerging Trends |

Print Speed | Moderate | High-Speed Printing |

Color Gamut | Limited | Expanded with Metallic Inks |

Automation Level | Manual Setup | Fully Automated Systems |

Sustainability | Higher Energy Consumption | LED UV and Eco-Friendly Inks |

Personalization Options | Basic | Advanced VDP and AR Features |

Explore the Latest Cylinder UV Printing Innovations

To discover how Cylinder UV Printing Technology can transform your business and help you leverage the latest trends, check out our comprehensive guide:

Cylinder UV Printer: Transforming Custom Printing Solutions

Final Thoughts

As Cylinder UV Printing Technology continues to evolve, embracing emerging trends can help businesses stay competitive, improve efficiency, and offer innovative products to their customers. From high-speed printing and advanced 3D effects to IoT-enabled automation and eco-friendly solutions, staying informed about these trends positions your business for long-term success.